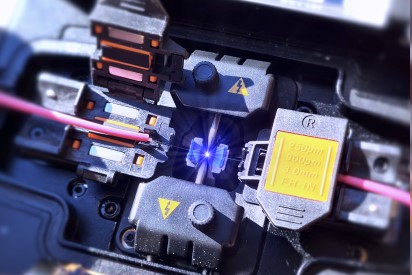

State-of-the-Art Splicing Technology

Thanks to the core centering and extensive automatic functions, CFS-100 is extremely precise and very easy to use.

Compatibility that is second to none

Whether multimode, singlemode fibers, pigtails, patch cables or SOCs: CFS-100 splices all common fiber types

Workflow at the Splice Station

Set up your splice station according to your ideas. Thanks to the foldable display, you can operate the device from the front and back.

The lightweight and flexible precision splicer allows splicing of G.651 fibers with a splice loss below 0.01 dB and of G.652 fibers below 0.02 dB (typical).

Equipped with detachable universal retention clamps, SOC clamps and internal thermometer and barometer, the CFS-100 can be used anywhere. Fast five seconds start up time and an average of nine seconds per splice as well as the automatic heating furnace for shrink sleeves speed up the workflow and leads to more splices per time.

The CFS-100 supports the user in troubleshooting and quality estimation bydetecting the cleave break angle, the core axis offset, the cleanliness of the fiber and the splice loss.

Create your own limit values and define them in profiles. Before each splicing process, an analysis of the splicability of the fibers and a fiber cleaning via cleaning arc is carried out. If the prospect of a satisfactory splice result is not good enough, the device cancels the process to save time-consuming rework. Re-ARC allows the subsequent improvement of the splice result.

If desired, splicing and shrinkage can be defined in detail in different profiles. Ifthe user doesn`t want to set them up manually, a fully automatic detection of the fiber type can also be carried out and the device determines the required parameters itself.

| Technical Data | Fusion Splicer CFS100 |

|---|---|

| Alignement methode | Core alignment (3-axis-controlled) |

| Supported fiber categories | Singlemode, multimode |

| Fiber types and loss values |

ITU-T G.651 (MM) ≦ 0.01 dB (typical) ITU-T G.652 (SM) ≦ 0.02 dB (typical) ITU-T G.653 (SM DSF) ≦ 0.04 dB (typical) ITU-T G.655 (SM NZ-DSF) ≦ 0.04 dB (typical) ITU-T G.657 (SM BIF) ≦ 0.02 dB (typical) EDF ≦ 0.04 dB (typical) |

| Ø Cladding supported | ~ 80 - 150 μm |

| Ø Coating supported | ~ 100 - 1000 μm |

| Splice time | Ø ≤ 9 s (depending on mode and fiber orientation) |

| Splicing processes per electrode | ≥ 5000 splicing operations |

| Splice modes | Automatic and manuel control |

| Heating time shrink oven | ≤ 25 s, adjustable |

| Battery time | ≥ 200 splice and shrink operations |

| Order-No. | NP-CFS100 |